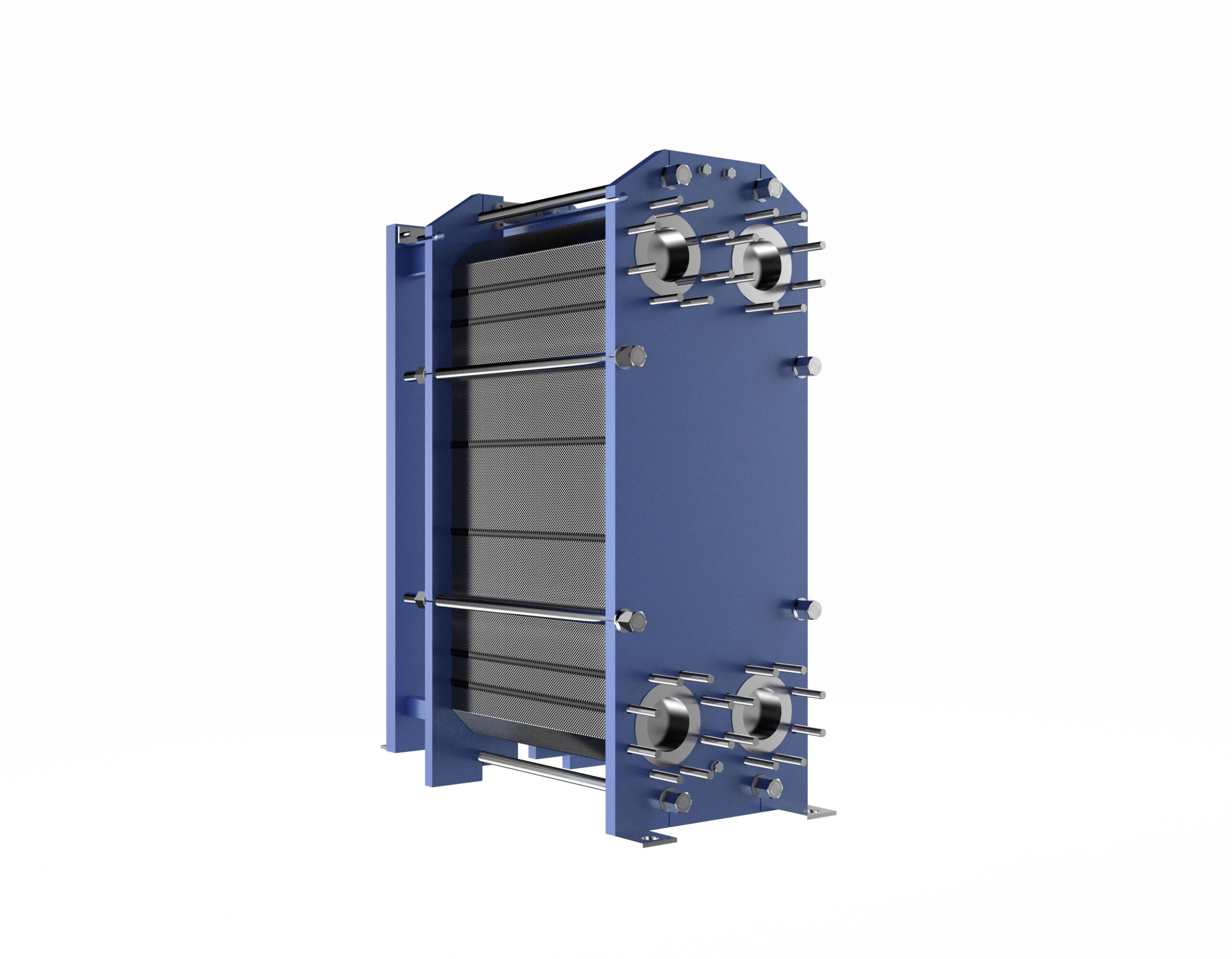

TIVO Gasketed Plate Heat Exchanger

The Perfect Combination of High Flow Rate and Ultimate Maintainability

Our gasketed plate heat exchanger features modular design with corrugated metal plates secured by sealing gaskets. It delivers exceptional heat transfer efficiency while providing maximum flexibility.

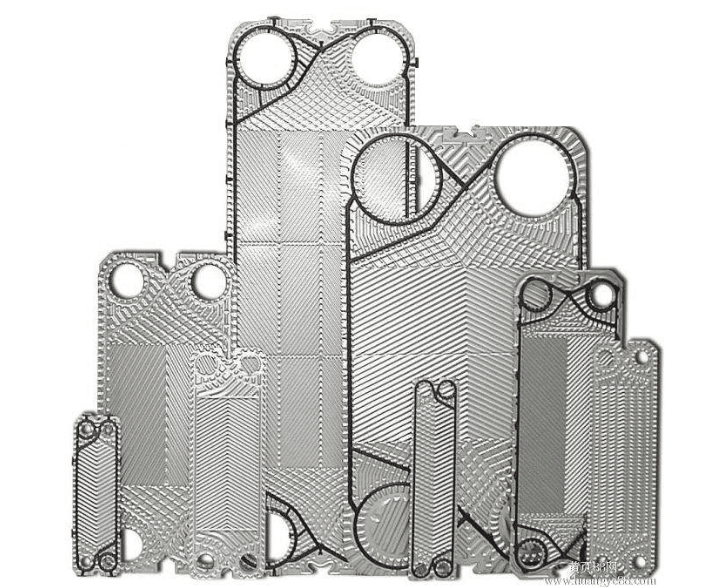

Gasketed Plate Heat Exchanger

Premium industrial-grade heat exchangers engineered for maximum efficiency, durability, and ease of maintenance across demanding applications.

Removable Plates

Easy maintenance and cleaning with fully removable plate design

High Efficiency

Optimized heat transfer with advanced plate geometry

Multi-Material

Available in 316L, titanium, and specialized alloys

Custom Design

Tailored solutions for specific industrial requirements

Technical Specifications

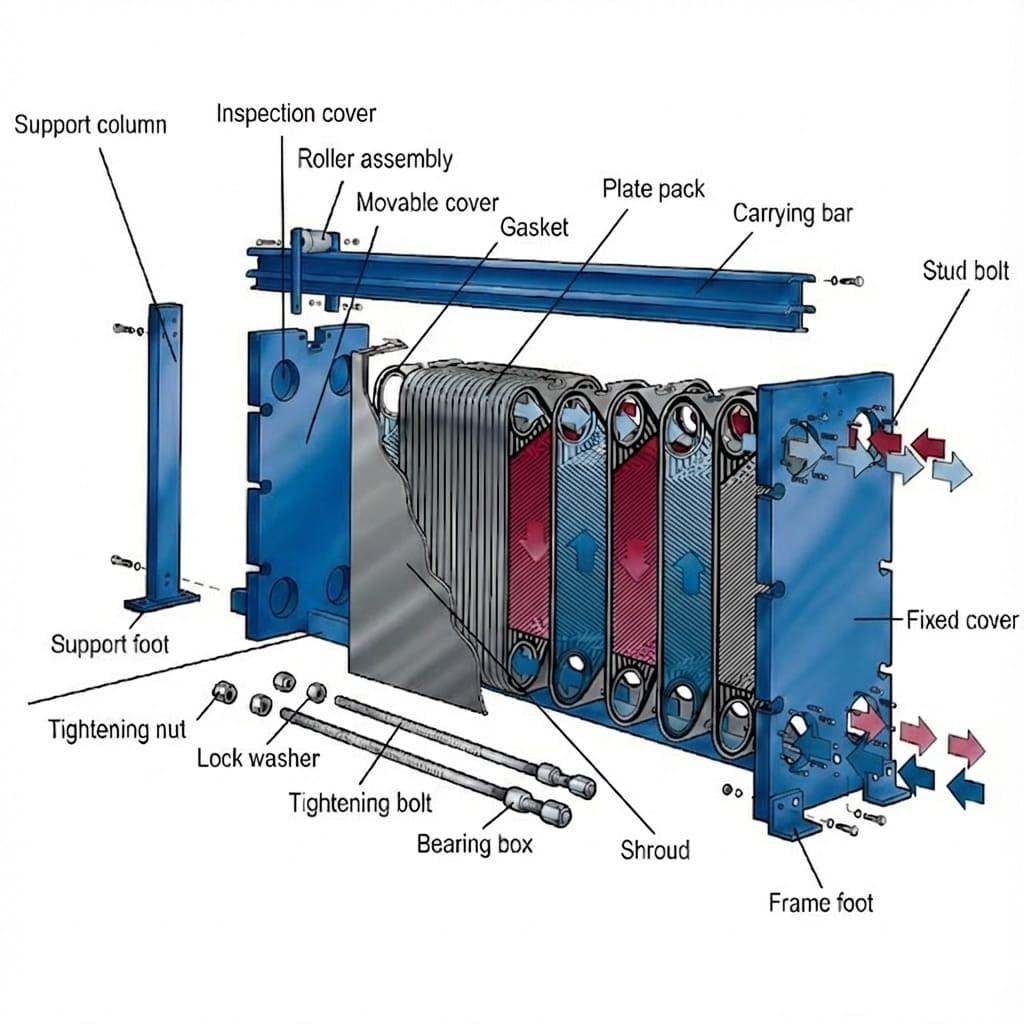

Precision Engineering & Core Components

Every component is precisely calculated to ensure zero-leakage operation under long-term high-pressure conditions

Frame & Pressure Plate

Heavy-duty steel plates providing uniform compression force to the plate pack, ensuring consistent sealing performance.

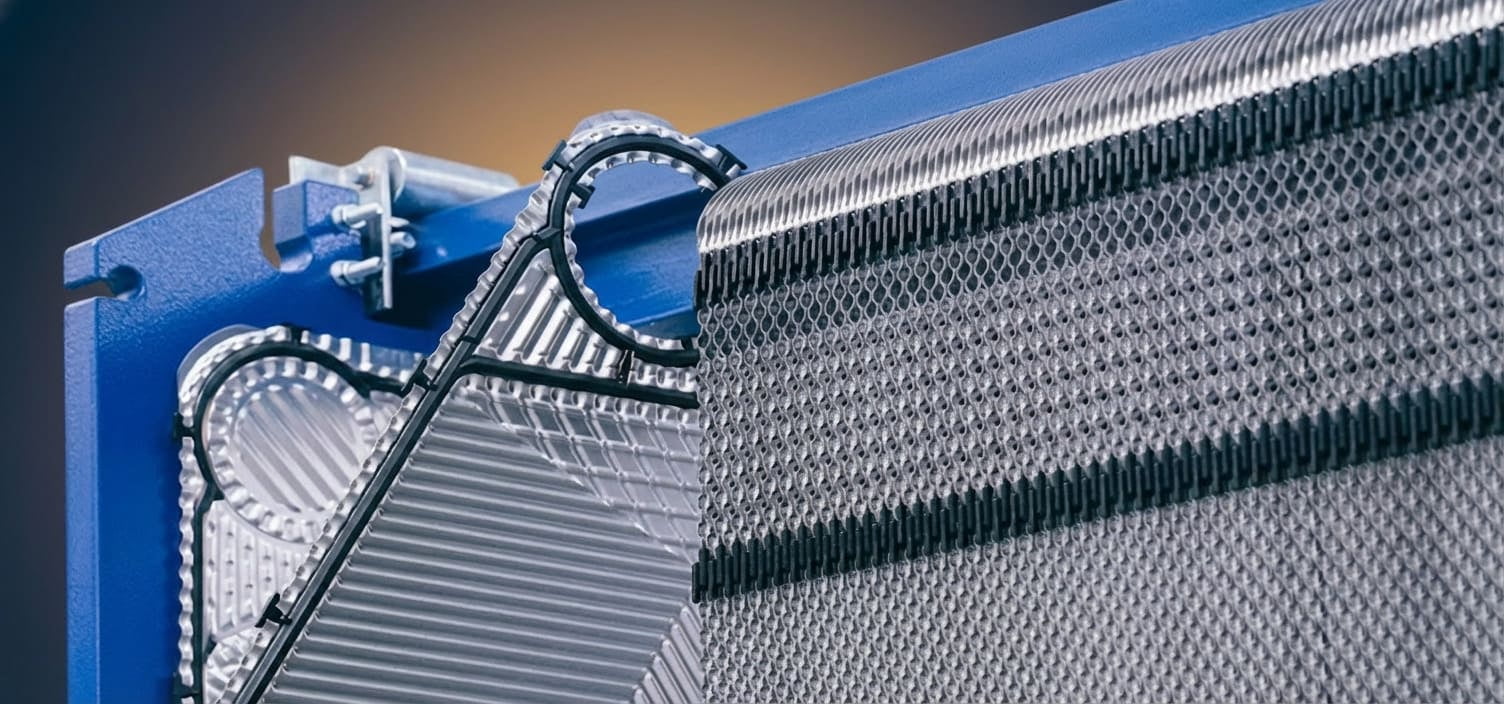

Heat Transfer Plates

Unique corrugated design (chevron pattern) enhances fluid turbulence, dramatically improving heat transfer coefficient.

Sealing Gaskets

Double sealing protection design with drainage grooves prevents cross-contamination between fluids.

Tie Rods & Bolts

Ensures precise plate alignment and enables quick disassembly for maintenance operations.

Why Choose Plate Heat Exchangers

Superior performance advantages over traditional shell-and-tube heat exchangers

High Heat Exchange Efficiency

Superior heat transfer performance with low operating costs. Our plate heat exchangers deliver 3-5 times better heat exchange efficiency compared to shell-and-tube heat exchangers.

Compact Design & Space Savings

Minimal footprint with easy installation. Occupies only 1/5 to 1/8 of the space required by shell-and-tube heat exchangers.

Plate HX

Compact

Shell-Tube HX

5-8x Larger

Convenient Maintenance

Easy to disassemble and clean. Simply loosen tie bolts to open the heat exchanger for mechanical cleaning, inspection, or plate replacement.

- Quick access to all plates

- Individual plate inspection

- Easy gasket replacement

Convenient Expansion

Flexible capacity adjustment without replacing the entire unit. Simply open the heat exchanger to increase the number of plates for enhanced performance.

Higher Efficiency

Space Required

Heat Recovery

Min Approach

Model Specifications

Comprehensive range engineered for diverse industrial requirements with precision manufacturing excellence

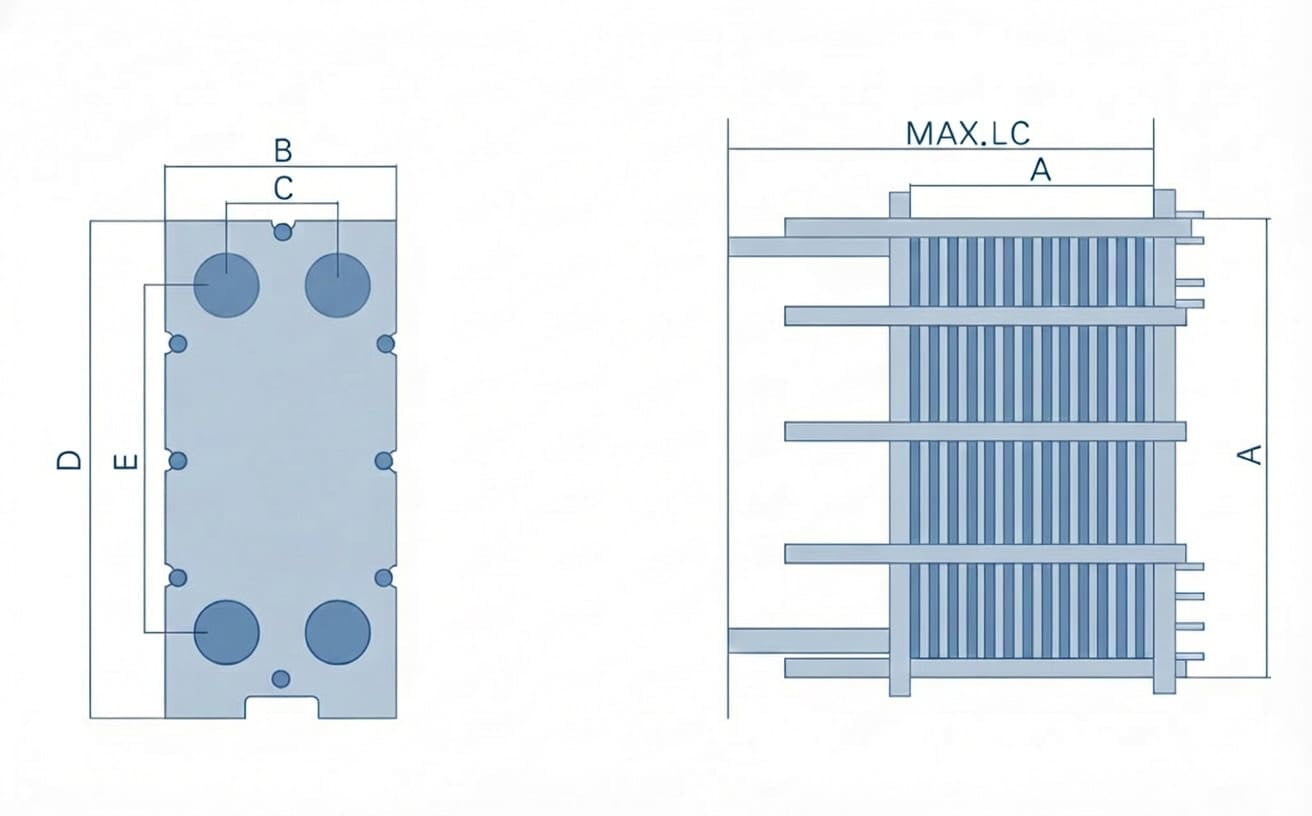

Dimensional Reference

Standard gasketed plate heat exchanger configuration

Standard Model Range

| Model | A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | MAX LC(mm) | Connection(mm) | Max Flow Rate(m3/h) | Deisgn Pressure(Mpa) | Max No. of Plates |

|---|---|---|---|---|---|---|---|---|---|---|

|

B30B

|

N(2.5+X) | 180 | 60 | 480 | 357 | 500 | 32 | 18 | 1.0 | 95 |

|

B60B

|

N(2.0+X) | 320 | 140 | 920 | 640 | 1200 | 50 | 36 | 1.6 | 250 |

|

B60H

|

N(3.0+X) | 320 | 140 | 920 | 640 | 1200 | 50 | 36 | 1.6 | 203 |

|

B100B

|

N(2.55+X) | 470 | 225 | 1069 | 719 | 1600 | 100 | 140 | 1.0/1.6/2.5 | 278 |

|

B100H

|

N(3.95+X) | 470 | 225 | 1069 | 719 | 1600 | 100 | 140 | 1.0/1.6/2.5 | 180 |

|

B150B

|

N(2.5+X) | 610 | 298 | 1815 | 1294 | 3000 | 150 | 360 | 1.0/1.6/2.5 | 600 |

|

B150H

|

N(3.95+X) | 610 | 298 | 1815 | 1294 | 3000 | 150 | 360 | 1.0/1.6/2.5 | 600 |

|

B200H

|

N(4+X) | 780 | 353 | 2260 | 1478 | 3000 | 200 | 600 | 1.0/1.6 | 480 |

|

B250B

|

N(2.5+X) | 920 | 439 | 2895 | 1939 | 3000 | 250 | 750 | 1.0/1.6/2.5 | 500 |

|

B350B

|

N(3.3+X) | 1150 | 596 | 2882 | 1842 | 4800 | 350 | 997 | 1.0/1.6 | 700 |

|

K60B

|

N(2.0+X) | 320 | 140 | 920 | 689 | 1200 | 50 | 36 | 1.6 | 250 |

|

K60H

|

N(3.0+X) | 320 | 140 | 920 | 689 | 1200 | 50 | 36 | 1.6 | 203 |

|

K100B

|

N(2.55+X) | 470 | 225 | 1051 | 763 | 1600 | 100 | 140 | 1.0/1.6/2.5 | 278 |

|

K100H

|

N(3.95+X) | 470 | 225 | 1051 | 763 | 1600 | 100 | 140 | 1.0/1.6/2.5 | 180 |

|

K130H

|

N(3.95+X) | 610 | 298 | 11591.4 | 1095.4 | 3000 | 150 | 360 | 1.0/1.6 | 600 |

Small Scale

HVAC systems, oil cooling, residential applications

Industrial

Power plants, chemical processing, large-scale operations

Industrial Applications

Solving critical heat transfer challenges across industries

Chemical & Petroleum

Heating and cooling of acids, alkalis, salt solutions, and crude oil preheating with excellent corrosion resistance.

Food & Dairy

Hygienic pasteurization, juice heating, and edible oil cooling. Easy cleaning prevents bacterial growth.

HVAC Systems

District heating stations with pressure isolation, solving system pressure balance for high-rise buildings.

Marine Engineering

Seawater cooling with titanium plates, resistant to salt corrosion, compact and lightweight design.

Manufacturing Process Excellence

From precision testing to final assembly - witness our comprehensive quality control process

DPI Detection System

Advanced Dye Penetrant Inspection (DPI) ensures zero defects in our plate surfaces. This non-destructive testing method reveals even microscopic surface cracks and discontinuities.

- Fluorescent penetrant inspection for maximum sensitivity

- UV light examination reveals hidden defects

- 100% plate surface integrity verification

Precision Plate Pressing

State-of-the-art hydraulic pressing technology creates perfectly formed corrugated plates with precise chevron angles for optimal heat transfer efficiency.

Professional Assembly Process

Expert technicians assemble each gasketed plate heat exchanger with meticulous attention to detail, ensuring proper plate alignment and gasket positioning.

- Sequential plate arrangement verification

- Precise tightening torque application

- Quality checkpoint at each stage

Rigorous Pressure Testing

Every heat exchanger undergoes comprehensive hydrostatic pressure testing at 1.25-1.5 times design pressure to guarantee leak-free performance in real-world applications.

Comprehensive Gasket Inspection

Advanced quality control ensures every gasket meets strict dimensional and material specifications for reliable sealing performance across all operating conditions.

Premium Finished Products

Each completed heat exchanger represents the culmination of precision engineering, quality materials, and rigorous testing - ready to deliver reliable performance in demanding industrial applications.

Quality Guarantee

- ✓ Complete batch traceability documentation

- ✓ Performance test certificates included

- ✓ ISO 9001 quality management compliance

- ✓ Global warranty and support coverage

YOU MAY ALSO LIKE

Explore our complete range of industrial heat exchange solutions designed for your specific applications

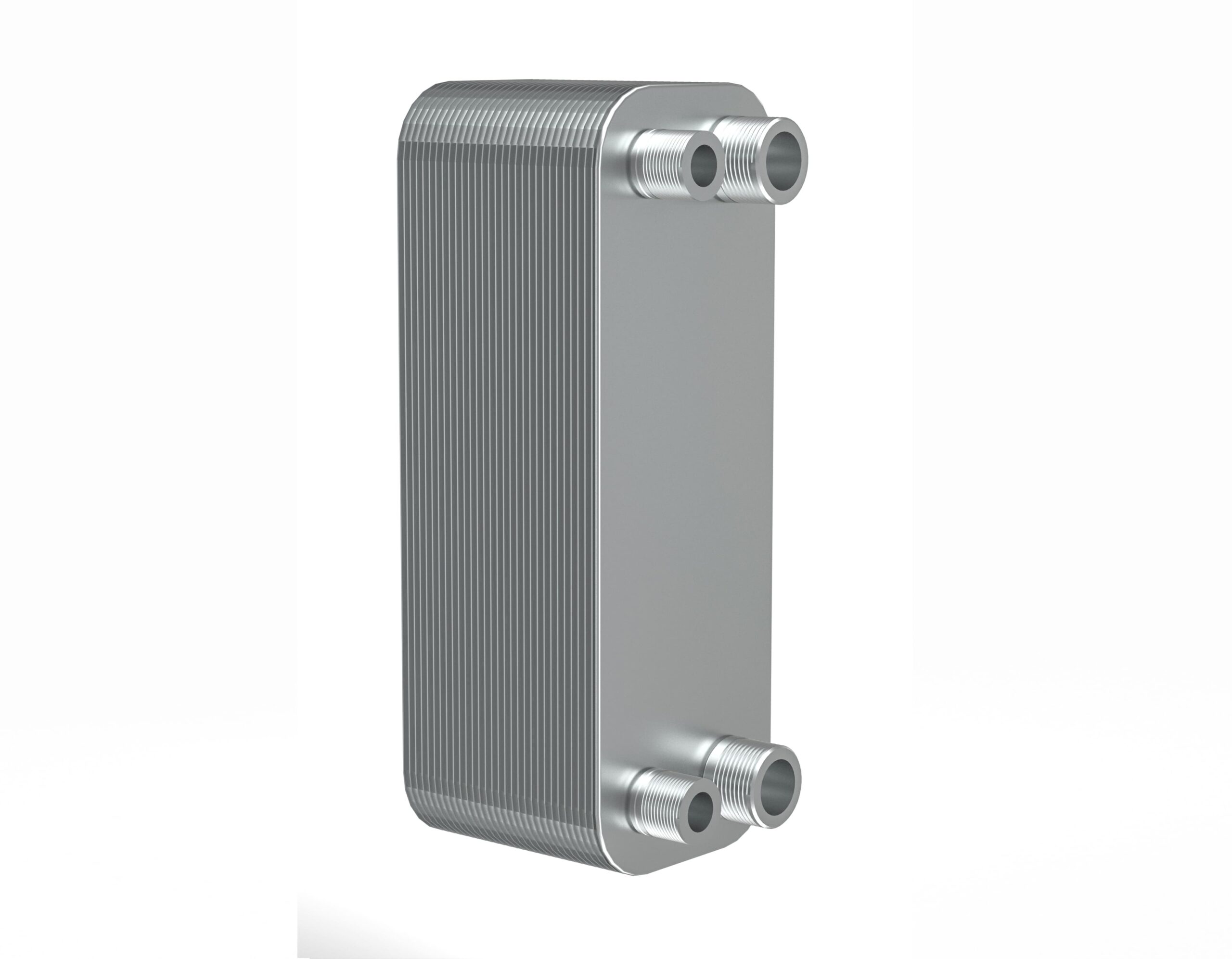

Brazed Plate Heat Exchangers

Plates & Gaskets

Fusion Bonded Plate Heat Exchangers

Contact Us

Get in touch with our team for heat exchanger solutions. We'll respond to your inquiry within 24 hours.