About TIVO

15 Years of Industrial Heat Exchange Excellence

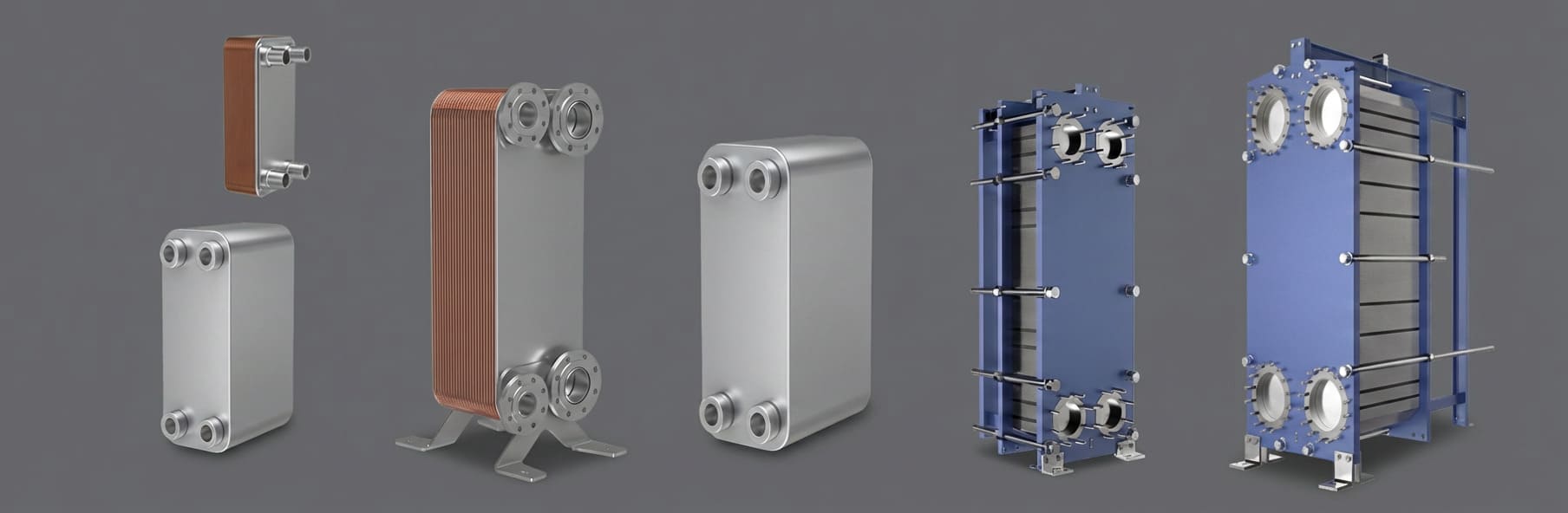

TIVO is a leading manufacturer specializing in plate heat exchangers and accessories R&D, production and export, with over 15 years of OEM/ODM experience. We are committed to providing efficient, energy-saving, and reliable heat exchange solutions for global customers.

Years Experience

OEM/ODM expertise

Annual Capacity

Heat exchangers produced

Global Markets

Countries served

Production Lines

Complete manufacturing

Our Story

Founded with a vision to revolutionize industrial heat exchange technology, TIVO has grown from a small manufacturing workshop to a global leader in plate heat exchanger solutions. Our journey began with a simple commitment: to deliver superior quality products that exceed our customers' expectations.

Today, we operate state-of-the-art manufacturing facilities equipped with advanced automation systems, serving industries ranging from food processing and chemical manufacturing to data center cooling and renewable energy systems.

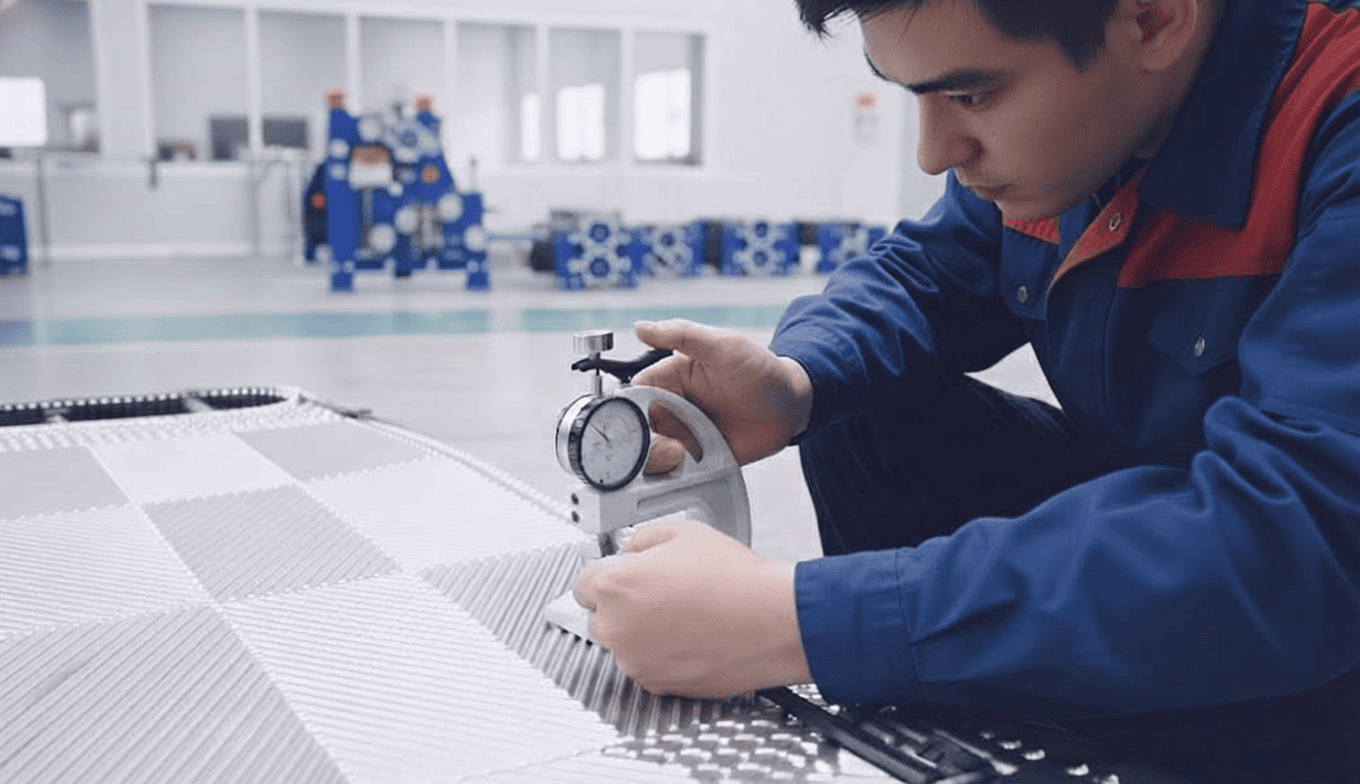

Manufacturing Excellence

Our modern production facilities combine advanced automation with rigorous quality control to deliver world-class heat exchange solutions.

Automated Assembly

Quality Testing

100% pressure and leak testing before shipment

Production Capabilities

Advanced Equipment

Fully automated pressing, laser cutting, and rubber injection systems ensure consistent quality and precision in every product.

Quality Control

Standardized assembly processes with strict quality inspection lines guarantee product reliability and performance.

Fast Delivery

Standard orders delivered in 7-15 days with support for various materials, corrugations, and custom OEM/ODM structures.

Quality & Certifications

We maintain strict quality management systems with full traceability from raw materials to finished products. Our commitment to excellence is validated by international certifications and rigorous testing procedures.

ISO 9001 Quality Management

Certified quality management system ensuring consistent product excellence

CE Certification

European conformity marking for safety and quality standards

UL Listed

Underwriters Laboratories safety certification for North American markets

Quality Control Process

- 100% raw material composition testing

- Water pressure and leak testing before shipment

- Complete batch management and traceability system

- Dedicated quality inspection team oversight

Global Reach

Our products are exported to 80+ countries worldwide, serving engineering companies, equipment manufacturers, end-user factories, and global spare parts distributors.

Worldwide Distribution

Europe

- Germany

- Italy

- United Kingdom

- France

Southeast Asia

- Indonesia

- Malaysia

- Thailand

- Vietnam

Middle East

- Saudi Arabia

- UAE

- Qatar

- Turkey

Americas

- United States

- Canada

- Mexico

- Brazil

Engineering Companies

Custom solutions for complex industrial projects and system integration requirements

Equipment Manufacturers

OEM partnerships for integrated heat exchange solutions in industrial equipment

End-User Factories

Direct supply to industrial facilities for new installations and equipment upgrades