Industry-leading features that set our BPHE apart from traditional heat exchangers

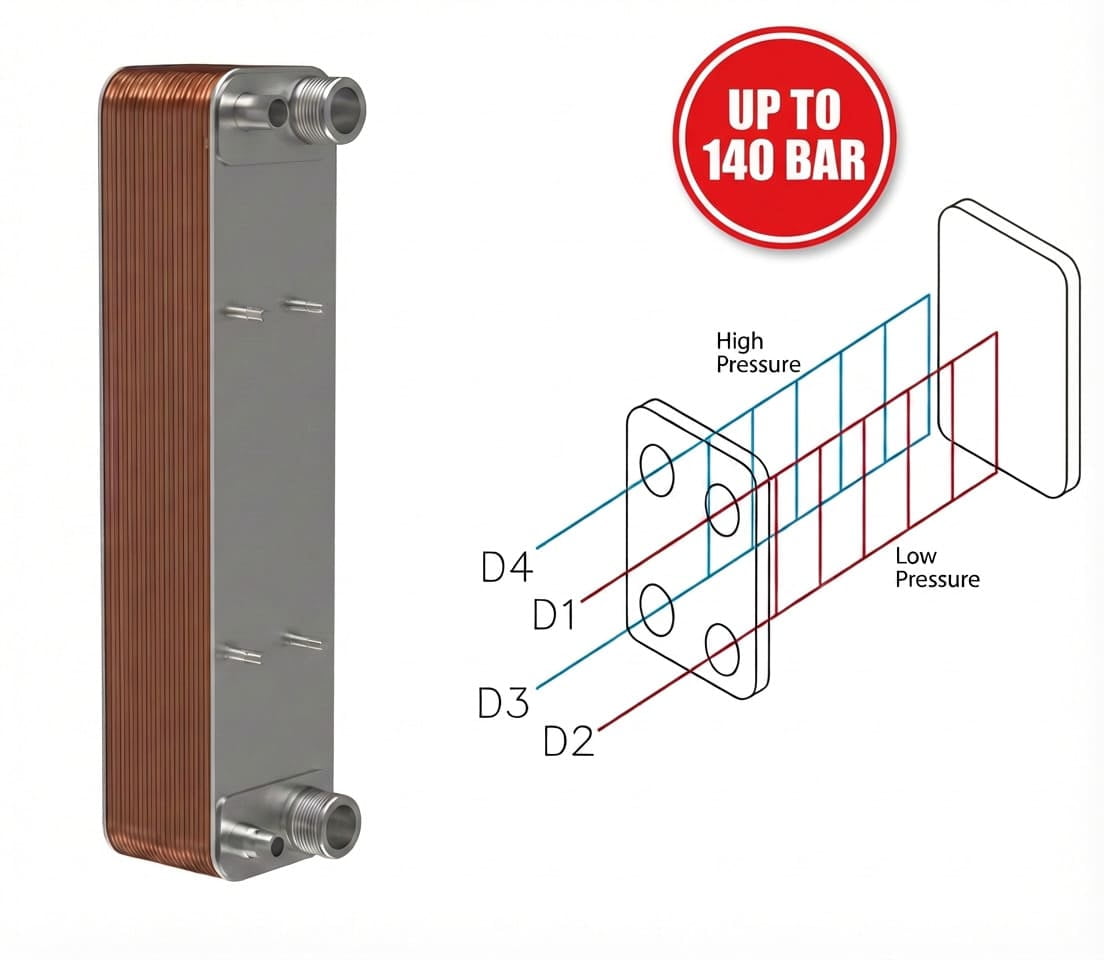

Covers multiple pressure levels from 1.0MPa to 14.0MPa for diverse applications

Saves up to 75% space compared to traditional shell-and-tube heat exchangers

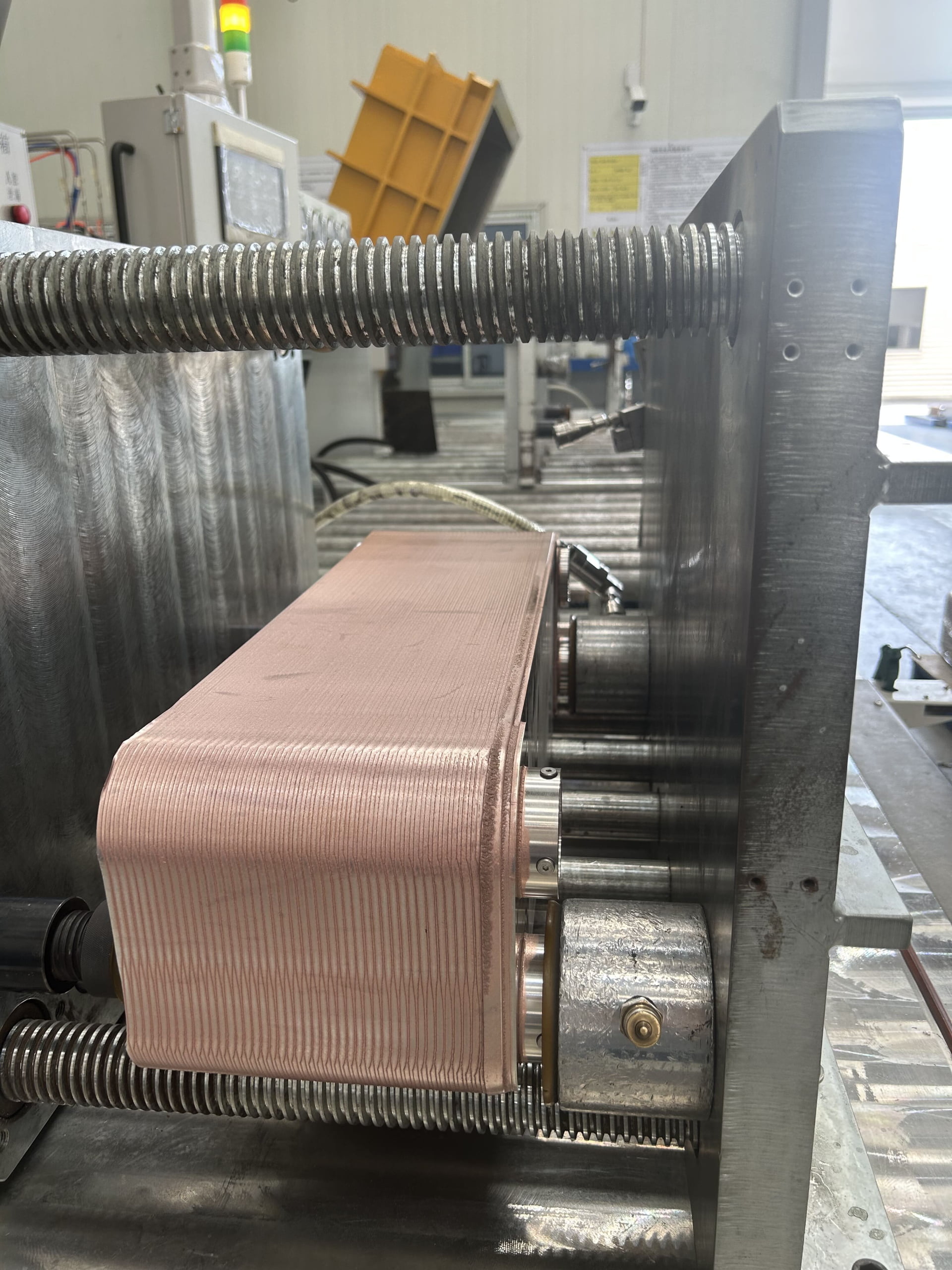

Standard AISI 316L stainless steel with 99.9% pure copper brazing

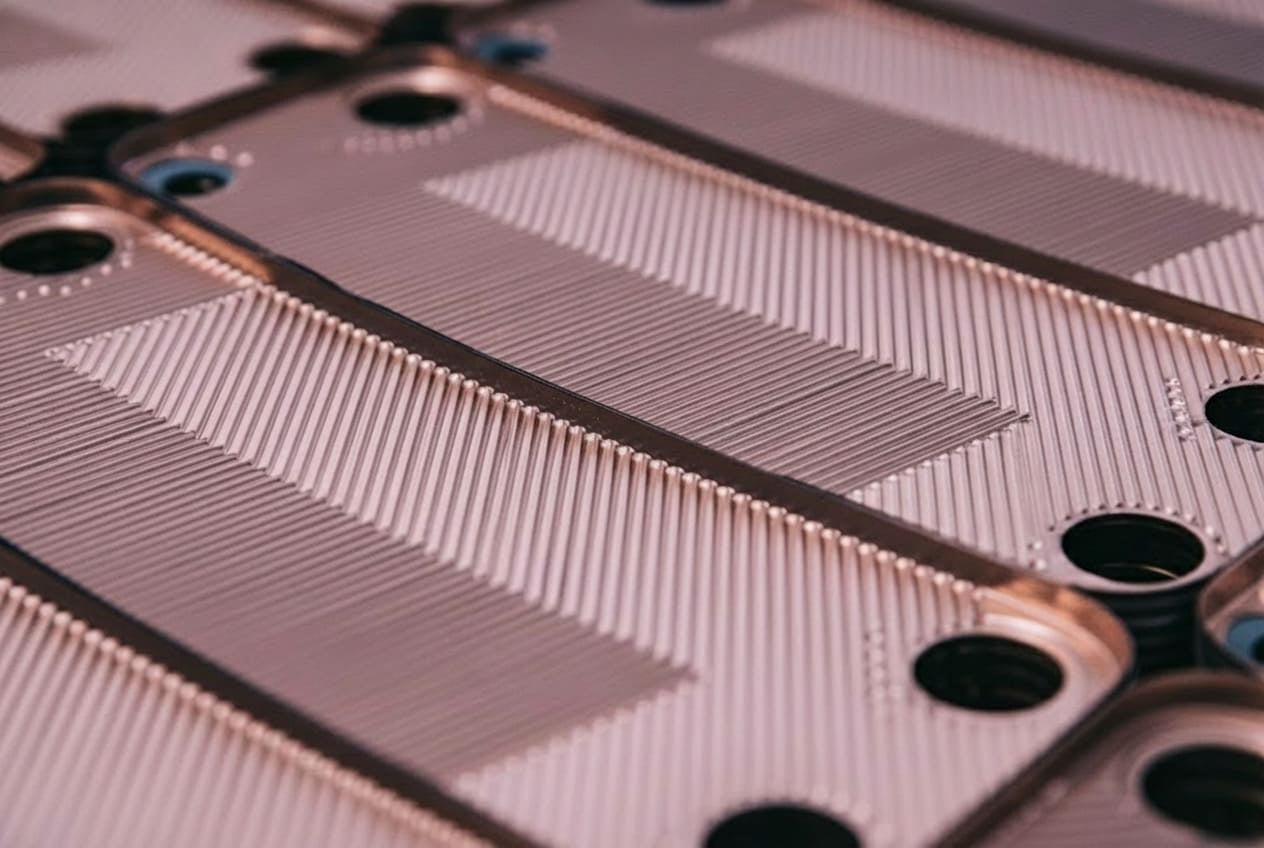

Chevron corrugated plates prevent scaling and maximize heat transfer efficiency

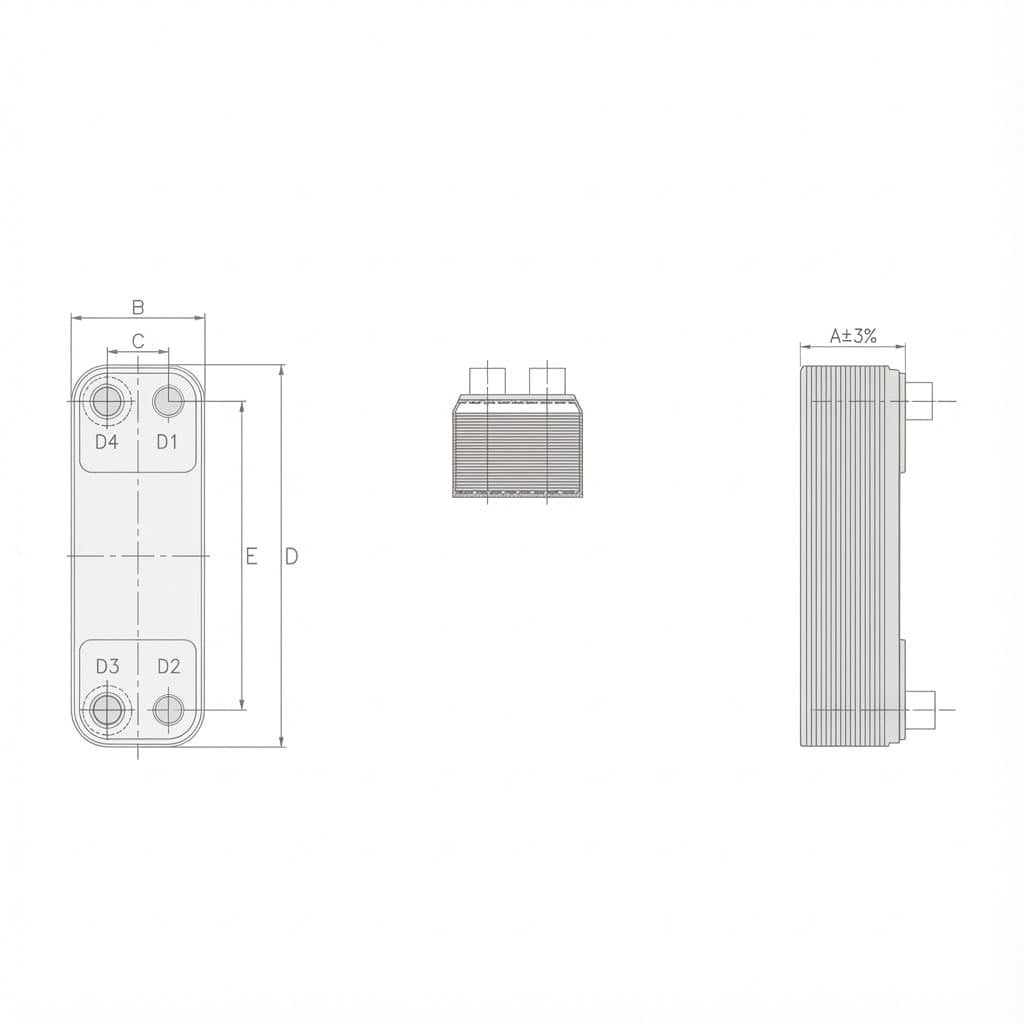

Comprehensive range of models with detailed parameters for precise selection

| Model | B (mm) | C (mm) | D (mm) | E (mm) | Thickness(mm) | Weight(Kg) | Max Flow (m³/h) | Design Pressure (MPa) |

|---|---|---|---|---|---|---|---|---|

| TV14 | 77 | 42 | 206 | 172 | 9+2.3N | 0.7+0.06N | 8 | 3 / 4.5 |

| TV16 | 78 | 42 | 208 | 172 | 9+2.24N | 0.6+0.049N | 8 | 1 / 3 / 4.5 |

| TV18 | 95 | 50 | 210 | 165 | 7+3.1N | 0.7+0.06N | 8 | 1 / 3 / 4.5 |

| TV20A | 93 | 40 | 323 | 269 | 9+1.5N | 1+0.09N | 8 | 1 |

| TV20B | 78 | 42 | 318 | 282 | 9+2.3N | 1+0.08N | 8 | 3 / 4.5 |

| TV20C | 77 | 42 | 313 | 278 | 10+1.28N | 0.9+0.07N | 8 | 3 / 4.5 |

| TV26 | 111 | 50 | 310 | 250 | 10+2.32N | 1.3+0.12N | 18 | 3 / 4.5 |

| TV26F | 107 | 50 | 317 | 250 | 10+1.98N | 1.3+0.1N | 18 | 3 / 4.5 |

| TV28B | 120 | 72 | 290 | 243 | 10+2.36N | 1.5+0.133N | 18 | 3 / 4.5 |

| TV28C | 120 | 63 | 290 | 234 | 10+2.36N | 1.5+0.133N | 18 | 3 / 4.5 |

| TV30 | 126 | 70 | 307 | 250 | 10+2.35N | 2.2+0.16N | 18 | 3 / 4.5 |

| TV42A | 121 | 68 | 332 | 279 | 10+1.53N | 2.05+0.11N | 18 | 3 / 4.5 |

| TV52 | 111 | 50 | 526 | 466 | 9+2.32N | 2.6+0.21N | 18 | 3 / 4.5 |

| TV53 | 106 | 50 | 522 | 466 | 9+2.1N | 2.6+0.27N | 18 | 3 / 4.5 |

| TV62 | 120 | 63 | 528 | 470 | 10+2.35N | 2.379+0.194N | 18 | 3 / 4.5 |

| TV62F | 120 | 63 | 527 | 470 | 10+1.98N | 2.379+0.18N | 18 | 3 / 4.5 |

| TV65 | 125 | 65 | 540 | 480 | 11+2.28N | 2.5+0.228N | 18 | 3 / 4.5 |

| TV95 | 189 | 92 | 616 | 519 | 11+2.7N | 7.8+0.44N | 42 | 3 / 4.5 |

| TV95F | 182 | 92 | 609 | 519 | 12+2.05N | 15+0.36N | 42 | 3 / 4.5 |

| TV120 | 246 | 174 | 528 | 456 | 10+2.34N | 7.2+0.52N | 42 | 3 / 4.5 |

| TV190 | 303 | 179 | 695 | 567 | 13+2.3N | 12+0.61N | 100 | 1.6 / 2.1 / 3 |

| TV200 | 320 | 188 | 742 | 603 | 14+2.7N | 13+0.67N | 100 | 1.5 / 2.1 / 3 |

| TV202 | 319 | 188 | 741 | 603 | 16+2.85N | 13+0.957N | 100 | 2.1 / 3 |

Varies by model: from 9+1.5N to 16+2.85N (N = number of plates)

Model-dependent formulas, e.g., 0.7+0.06N (kg)

Versatile solutions across multiple industries and specialized applications

Advanced testing procedures and precision detection equipment ensure exceptional performance and reliability for every brazed heat exchanger

ASTM B117 compliant salt spray testing for 1000+ hours to verify corrosion resistance of stainless steel brazed joints and copper brazing materials.

Automated plate stacking system with ±0.1mm precision ensures perfect alignment and optimal brazing joint formation for maximum heat transfer efficiency.

Ultra-sensitive helium mass spectrometer detection with sensitivity down to 10⁻¹⁰ mbar·l/s ensures zero-leakage performance for critical applications.

Comprehensive quality assurance protocol ensuring every brazed heat exchanger meets the highest standards

PMI testing and chemical composition analysis for all stainless steel plates

Automated plate alignment with micron-level precision control

X-ray inspection and visual verification of brazing joint integrity

Hydrostatic pressure test at 1.5× design pressure for 30 minutes

Ultra-sensitive leak detection for zero-tolerance applications

Provide detailed working conditions for accurate heat exchanger selection and sizing

Need immediate technical consultation? Contact our engineering team: