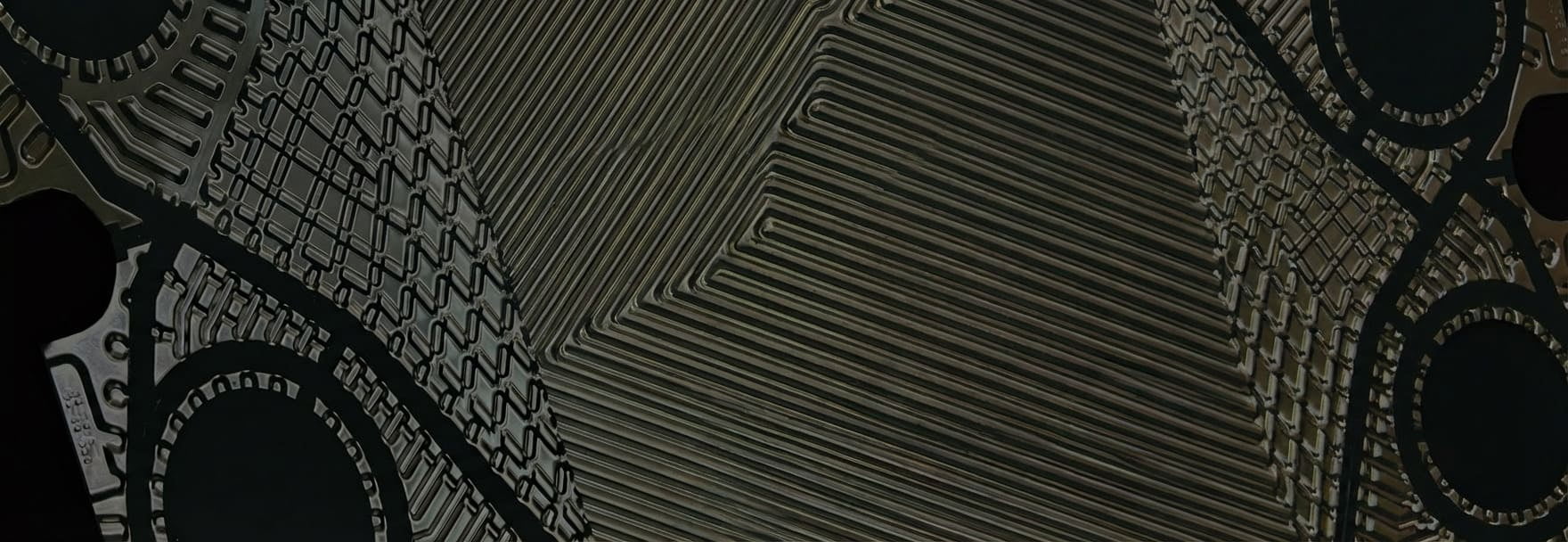

API SCHMIDT PLATE HEAT EXCHANGER

PLATES & GASKETS

Professional plate heat exchanger solutions with superior efficiency and reliability for industrial applications worldwide.

API SCHMIDT SERIES Plate Heat Exchangers Plates and Gaskets Spare Parts

Professional plate heat exchanger manufacturing with over 15 years of OEM/ODM experience.

TIVO is a manufacturing enterprise specializing in the R&D, production, and export of plate heat exchangers and replacement plates and gaskets. We are committed to providing efficient, energy-saving, and reliable heat exchange solutions for global customers, with products widely used in industrial, energy, food processing, and data center liquid cooling applications.

Our main products include Gasketed Plate Heat Exchangers, Brazed Plate Heat Exchangers, Fusion Bonded Heat Exchangers, and compatible plates & gaskets for major brands including Alfa Laval, Gea, Apv , Tranter, Hisaka , Sondex, and Funke etc.

Available Models

Comprehensive range of heat exchanger models designed for various flow rates, pressures, and temperature requirements.

| S12 | S16 | S22 | S32 | S52 |

|---|---|---|---|---|

| Sigma 12 | Sigma 16 | Sigma 22 | Sigma 32 | Sigma 52 |

M Series - Standard gasketed plate heat exchangers for versatile applications

NEED A QUOTE?Material Specifications

Professional-grade materials engineered for demanding industrial applications. Our comprehensive material portfolio ensures optimal performance across diverse operating conditions.

Plate Materials

| Material | Grade | Applications | |

|---|---|---|---|

| Stainless Steel | SS304 | General purpose, food grade,Pure Water/Edible oil Ethanol | |

| Stainless Steel | SS316/316L | Water/ Edible oil/ Ethanol/ Carbonic acid/ 30% Sulphuric acid | |

| Titanium | Ti Gr.1/2 | Seawater, chloride solutions | |

| Hastelloy | C276 | Organic acid / High temperature HF acid/ Hydrochloric acid (<40%) / Phosphoric acid (< 50%) / Chloride / Fluoride |

Plate Material Selection

Material selection depends on operating temperature, pressure, fluid chemistry, and corrosion requirements. Our engineering team provides material recommendations based on your specific application.

Gasket Materials

| Material | Temp Range | Applications |

|---|---|---|

| NBR | -30°C to +120°C | General purpose, oil resistant |

| EPDM | -54°C to +150°C | Steam, hot water, glycol |

| HNBR | -30°C to +160°C | Enhanced oil resistance |

| VITON A(FKM) | -15°C to +180°C | Excellent chemical resistance |

| VITON G(FKM) | -15°C to +200°C | Chemical resistance, high temp |

Gasket Material Selection

Gasket material selection is critical for sealing performance and service life. Consider fluid compatibility, temperature range, pressure conditions, and cleaning requirements.

Material Expertise

15+ years of material selection experience across diverse industrial applications and operating conditions.

Quality Assurance

100% material traceability and certification compliance with international quality standards.

Custom Solutions

Tailored material combinations and specifications to meet your unique process requirements.

Contact us if you did not find the brand model you need

Get expert consultation within 24 hours

Related Products

Explore other heat exchanger solutions that might meet your requirements.