Top 10 Plate Heat Exchanger Manufacturers in China: A 2026 Strategic Sourcing Guide

# Top 10 Plate Heat ...

Complete heat exchanger solutions engineered for industrial excellence and global compatibility.

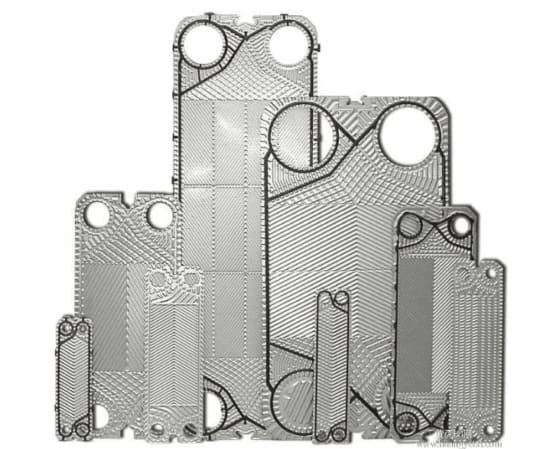

Premium replacement components compatible with major global brands.

View Details

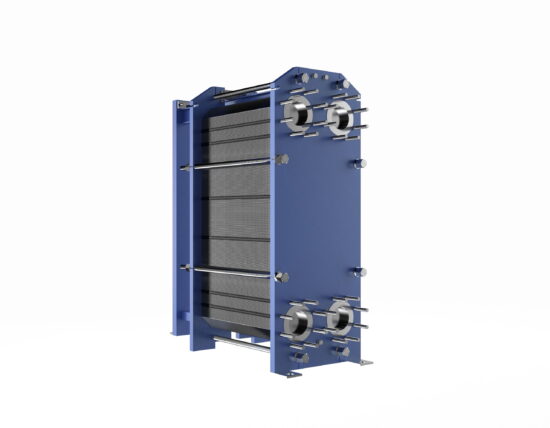

Advanced design with removable plates for easy maintenance.

Explore Features

Maintenance-free solution for HVAC and data centers etc.

Technical Specs

All-stainless steel construction for extreme conditions.

Explore ApplicationsOur engineering team provides comprehensive consultation and custom manufacturing for specialized industrial applications.

16 complete production lines with state-of-the-art automated systems.

State-of-the-art vacuum brazing furnaces ensure superior joint quality and metallurgical bonding.

Fully automated production lines with intelligent robotics and laser cutting systems.

Advanced hydraulic pressing machines create precise corrugation patterns.

Precision-engineered with rigorous quality management and complete traceability from raw material to final product.

100% verification of all raw materials

Hydraulic & helium leak detection

Scalable Production & Rapid Delivery

304/316L, Titanium, Hastelloy, 254SMO for superior corrosion resistance

Flow distribution & thermal verification with precision instruments

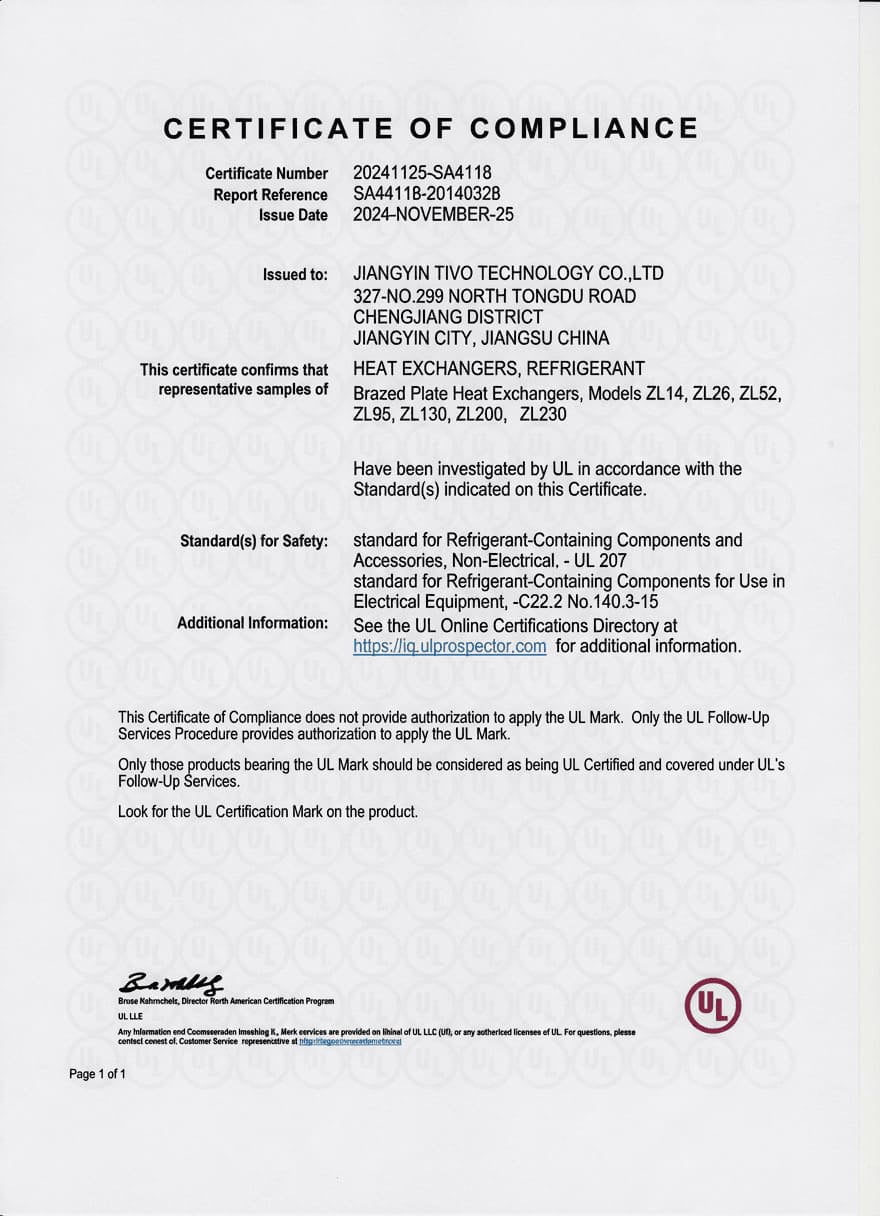

ISO 9001, CE certified for international compliance

Complete batch management system for quality assurance

Quality Management

Pressure Equipment

Safety Standards

Real results from industry leaders who trust TIVO solutions.

Operations Director

Premium Dairy Co.

"Our milk pasteurization line achieved 35% energy savings after installing TIVO's gasketed heat exchangers. The maintenance team loves how easy they are to clean and service."

Chief Technology Officer

CloudTech Solutions

"TIVO's brazed heat exchangers transformed our CDU performance. We achieved better cooling efficiency with 40% less space requirement. Outstanding engineering support throughout the project."

Process Engineer

PetroChemical Industries

"The 316L stainless steel plates handle our aggressive chemicals perfectly. Three years of operation with zero corrosion issues. TIVO's quality is unmatched."

Facility Manager

Metro Office Complex

"Replaced our old system with TIVO's heat pump solution. The building's energy costs dropped dramatically, and tenant comfort improved significantly. Excellent ROI."

Let our engineering team help you achieve similar results with customized heat exchanger solutions.

Stay updated with the latest technical insights and support documentation for heat exchanger solutions

# Top 10 Plate Heat ...

Operating an APV B s...

Connect with our experts and receive exclusive technical resources.

50-page technical guide for sizing

Database for all major brands

Energy savings calculation tool